If you’re rusting multiple panels, or you’d simply like to shorten this step, you’ll want to use an orbital sander. It can rotate several hundred or thousand times per minute, applying a rapid pressure that even the strongest arms struggle to recreate. Orbital SanderĪ sanding block is fine, but an orbital sander could make short work of this step. It’s made of durably carbon steel bristles and features a unique curved handle. The Forney Wire Brush (available on Amazon) is an excellent example of a wire brush that can help scuff up your corrugated panel. That way, you can cover more areas in a shorter amount of time. These come in several shapes and sizes, but you may want to choose one with a long brush head. If you’d rather keep your arms away from exposed steel, you can scrap your panel with a firm metal wire brush. Of course, you could opt to use a wire brush instead. Even with a thick pair of gloves on, your hands may begin to ache after scrubbing with a steel pad. However, a steel abrasive pad can also be challenging to hold, especially over an extended period.

It’s also fantastically affordable and accessible, being available at most grocery and department stores. Steel PadĪ steel pad, the kind used to scour dishes, is one of the simplest tools you can use to scrape and scratch your corrugated metal panel. Let’s briefly explore each of these options in greater detail to help you choose the best tool for the job and your budget. To scratch up the surface of your metal sheet, you’ll need the right tool. After all, even the most straightforward aluminum panels can be challenging to rust if they’re blemish-free.

#Pre rusted corrugated metal siding roofing free#

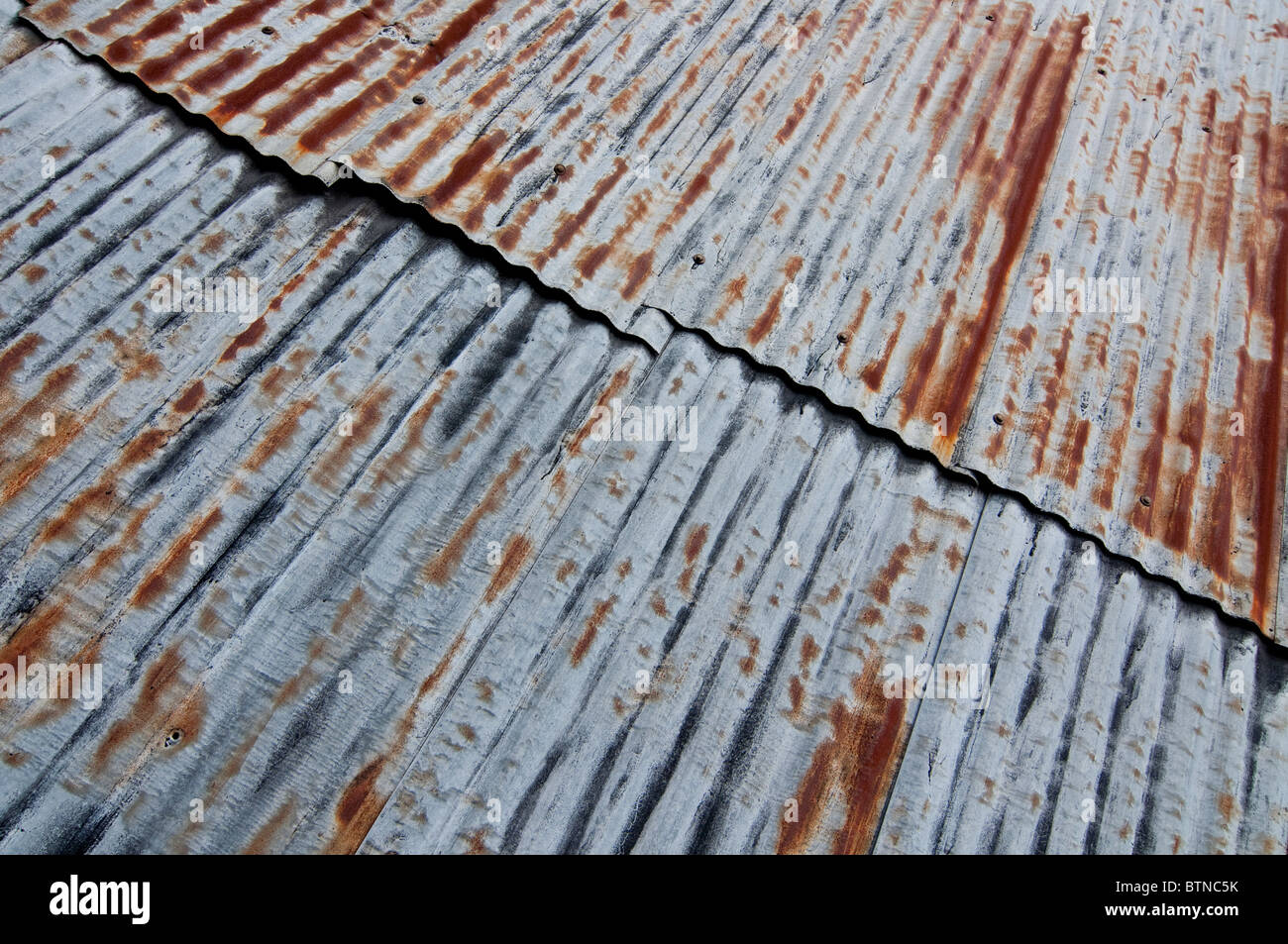

When your corrugated metal is free of dirt and grease, it’s time to start scraping. When you’ve gotten every last drop, you can go ahead and begin scraping your panel. After rinsing away any remaining suds, use a dry and unused bar towel to dry it off.Wipe down the surface of your corrugated metal sheet, making sure to keep the clean side facing upward.Agitate the water to form suds, then dip a clean bar towel into the solution.Fill the bucket up halfway with room-temperature water.Here are the steps to clean and dry corrugated metal: Consequently, go ahead and fetch a clean bucket, some gentle dish soap, and a handful of clean bar towels. That’s because oil and dirt can form a thin layer that makes it more challenging for your corrosive substances to penetrate the surface of your corrugated metal. Though this might seem counterintuitive, it’s crucial to remove any oil, grease, or dirt from the surface of your panels before using abrasive tools or substances. Clean and Dry the Corrugated Metalīefore you can start working toward rust formation, you’ll want to clean your metal sheeting. Not only will you be able to achieve a more uniform and speedy rusting, but you might also save a little money. Therefore, if you purchase panels made out of these metals, you may struggle to see any rust formation.Īs such, it’s often best to choose simple steel corrugated panels. After all, galvanized and stainless steel options are designed to resist rust and corrosion. It’s crucial to consider your chosen corrugated panel type when attempting to rust it. But perhaps the three most common types of metal used for this purpose are: There are quite a few different types of metal used to make corrugated panels.

However, this can be a little more challenging than it initially seems, especially when considering the multiple types of corrugated metal sheeting. Scrape the Surface of the Metal SheetingĪs you might expect, the first thing you’ll need to do to rust corrugated metal is acquire some metal panels.

0 kommentar(er)

0 kommentar(er)